MIG & TIG Welding Services

(Click on thumbnail to enlarge)

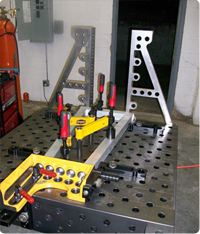

Wing Aluminium weldment for Army Trainer

|

|

welding fabrication

|

|

Offering a range of TIG and MIG welding services, including contract, production, small part, and large assemblies, NCAD Products, Inc. serves several major industry sectors. The welding department at NCAD utilizes the latest technology in both welding equipment and Modular fixturing.

Our high tech approach and attention to detail allows us to deliver accurate (~0.5 mm) and consistent products. Starting within our SolidWorks design suite, we begin with a full 3D fixture layout. Performing the fixture design within the 3D CAD system allows us to work through any possible design or fixturing issues and optimize how the critical components are fixtured to ensure that we meet our customers' requirements completely before material is even cut. This approach allows our staff to efficiently plan the work and manage our customers' expectations more effectively. |

No Cost - Weld Fixturing

By using a modular welding fixture system, the configuration can be set up and torn down again and again. It can fixture small assemblies, and can be changed to accommodate larger more sophisticated weldments. This dynamic flexibility allows NCAD to provide an infinite size capacity to the end customer without the cost of custom fixturing.

Value Added Services

NCAD is also happy to offer addition services, including engineering, prototyping, research and development, painting, and Assembly.

MIG & TIG Welding Services Capabilities

| General Capabilities |

Contract

Large Assemblies

|

Production

Small Parts | |

| Industry Focus |

Aerospace

Automotive

Marine |

Medical

Agricultural

Petrochemical | |

| Intended Applications |

Micro

Narrow Groove

Precision Assembly |

Sheet Metal

Structural

Tubular Frame | |

| Industry Standards |

ISO Registered

International Organization for Standardization

Mil-Spec Compliant

|

Military Specifications

AWS

American Welding Society | |

| Arc/Resistance Welding Process |

GMAW (Gas Metal Arc Welding)

Also known as metal inert gas or MIG welding.

GTAW (Gas Tungsten Arc Welding)

Also known as Tungsten Inert Gas (TIG) welding. This process uses a nonconsumable tungsten electrode, an inert gas and a separate filler material. This process is sometimes mistakenly referred to as Heliarc welding.

MIG

Metal Inert Gas welding, also referred to as Gas Metal Arc Welding.

TIG

Tungsten Inert Gas welding. Also referred to as Gas Tungsten Arc Welding. |

| Materials |

Aluminum

Exotic Metals

Metal

Stainless Steel |

Steel

Structural Steel

Titanium | |

| Welding Operation |

Free Hand |

| Additional Services |

Assemblies

Engineering

On-Site |

Prototype

Research and Development | |

| File Formats |

AutoCAD (DWG,DWZ)

DXF - Drawing Interchange Format, or Drawing Exchange Format

IGES - Initial Graphics Exchange Specification, ANSI file format.

SolidWorks (SLDPRT,SLDDRW,SLDDRT)

STEP - Standard for the Exchange of Product Model Data |

Back to Top |

NCAD Products, Inc.

NCAD Products, Inc. Oviedo, FL 32762-2188

Oviedo, FL 32762-2188 Fax: 866.370.8062

Fax: 866.370.8062 www.ncad.com

www.ncad.com Site Map

Site Map